Recently, large-scale airbag recalls have sparked public attention to the need to incorporate stringent quality standards into the manufacture of airbags. The impact on safety of these lifesaving equipment is a sign that consumer confidence has been eroded by relentless cost pressures on suppliers. To win back the trust of the public, OEMs are taking extraordinary steps to ensure the safety of their passengers. These aims to improve the quality of airbag control level of new measures brought additional challenges to first-tier suppliers. In the ever-changing airbag supply ecosystem, they are still focused on reducing the unit cost of airbags.

Increasingly complicated markets

With the average annual increase to 4% in light vehicle production by 2020, the airbag market is expected to achieve a compound annual growth rate (CAGR) of 8.1% during this period. In part because of the overall shift in growth stemming from the introduction of new safety regulations in India, China and other developing countries. By 2020, emerging economies are expected to account for 58% of global vehicle production. Only China will account for more than 30%. The production of commercial vehicles and passenger cars will exceed Western Europe and North America. For mature markets, increasing passive safety will enable new airbags to achieve a wider range of applications, such as in a single advanced vehicle can have up to 12 kinds of applications.

For most new vehicles, the driver side, passenger side and side curtain airbags are standard, while many passenger and light trucks are equipped with eight or more airbags. In addition, with the release of recommendations by the Automotive Safety Testing Agency, such as the New Car Evaluation Procedure (NCAP), to promote the use of larger, wider side impact airbags, the size of the airbag products have also been in development and evolution.

The innovative use of new airbags continues to deepen both inside and outside the vehicle. Volvo and Land Rover are currently offering pedestrian airbags for selected models on the European market. In the range of 20 to 50 km per hour, these airbags are designed to minimize certain frontal impacts. Other concepts still under development include a rear airbag mounted on the front seat and roof.

The challenge for the industry

Because of the aftermath of the airbag inflator scandal, the automaker has taken stringent measures to strengthen the inspection of the components of the airbag ignition system. The automated inspection system enables suppliers to ensure that their components meet stringent safety standards without slowing production schedule.

For the fabric part of the airbag, the type of inflator used generally determines the choice of material. In a similar way, automated visual inspection has become an important part of the quality monitoring process. However, the strengthening measures only exacerbate the complexity of the manufacturing process. Despite these new development initiatives, airbag suppliers still maintain the same cost targets to make a profit. Airbag manufacturers are reaching the limit of cost optimization, so there is an urgent need to find a solution to the plight of a sharp decline in costs. This explains why many manufacturers are using less expensive materials, such as polyester fibers.

However, the lower cost is bound to show weaknesses, because the intrinsic elastic properties of these materials tend to be more serious deformation.

Improve the road safety value chain

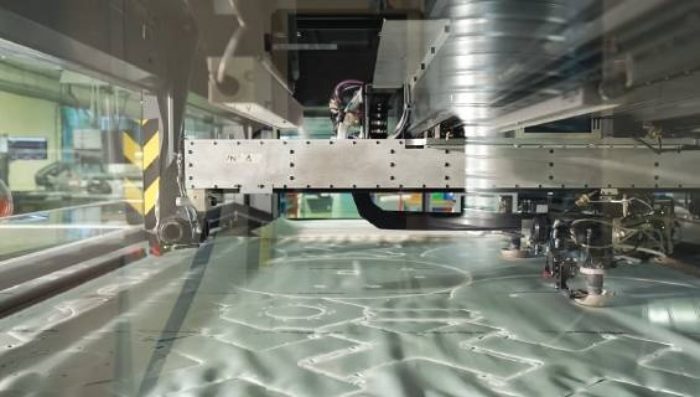

When combined with process optimization and resource optimization, the most advanced laser cutting technology can help airbag manufacturers overcome multiple business challenges. Advanced airbag design and cutting technology can meet these stringent new requirements, even in the use of low-cost materials such as polyester, but also to ensure that the final quality close to zero defects. By increasing productivity and efficiency, suppliers can achieve gains, remain competitive, and meet the increasingly demanding requirements of OEMs.

Identifying anomalies during the production process can result in severe losses such as downtime or expensive re-cutting, especially when the safety of the vehicle passengers is threatened. Today, the new airbag pre-production software and laser cutting machine is designed to standardize the entire production process by validating every step of the airbag fabric preparation process.

Since the geometry of the cutting part comes from the industrial design department, in various forms, the first step is to check the consistency the of unit and the scale. The second step is to remove all the geometries that are not needed for the cut, even if the naked eye is not visible.