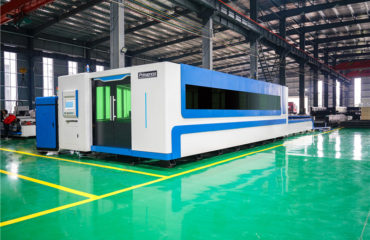

Features and Advantages of Fully Automatic Coil Fiber Laser Cutting Machine

Coil fiber laser cutting machine advantages:

- One piece of equipment can realize the four functions of leveling, feeding, cutting and unloading, breaking the traditional processing method.

- Automatic assembly line, online cutting of coil and net material, saving labor and improving efficiency.

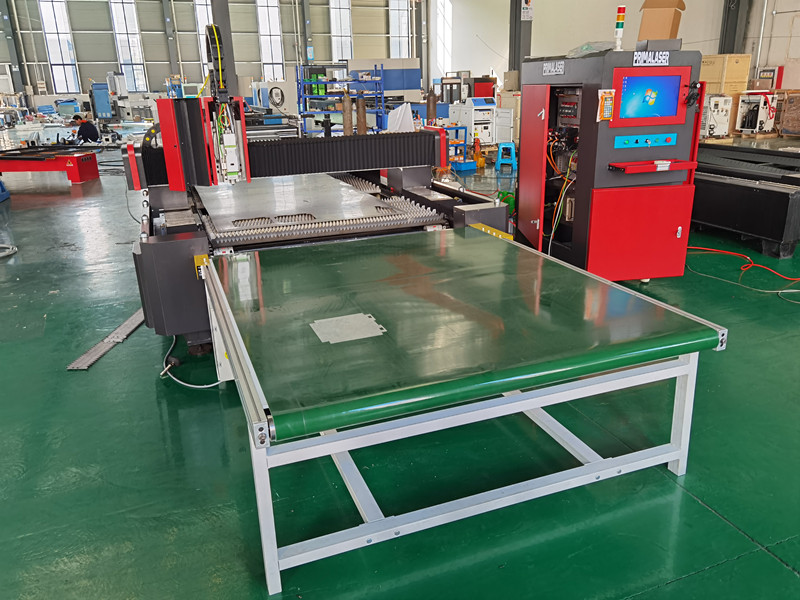

- Equipped with an independent and open automatic feeding system and automatic transmission operation platform, which completely solves the drawbacks of manual feeding.

- Adopt gantry double drive structure, imported screw rod and linear guide rail, stable transmission and high precision;

- During laser processing, the cutting area is closed to ensure the safety of operators.

- Intelligent typesetting of cutting graphics, support for importing multiple types of graphics, intelligent edge finding, improving the utilization rate of plates and reducing waste.

- The optical path is not restricted, the optical fiber transmission loss is small, and the processing range can be maximized

- Equipped with a complete dust removal system, energy saving and environmental protection, easy to remove smoke.

Advantages of practical application of coil laser cutting production line:

- Continuous cutting production, high equipment utilization rate. After the coil is uncoiled and leveled, it is fed into the laser cutting machine by the feeder above the rotating table for cutting. With the movement of the table, the process of cutting while feeding can be realized, which effectively shortens the cutting time of parts and improves the use of the equipment. efficiency.

- The production is flexible. It can respond to the needs of production changes at any time. When the required parts change, the two-dimensional graphics can be modified through programming software to cut out the required parts without changing the hardware structure of the equipment, and it has the flexibility to manufacture different products.

- It has the function of automatic typesetting to reduce the generation of excess waste. The cutting host system itself has the function of automatic typesetting, and it can be mixed and produced at any time according to the spare parts needed temporarily. The required parts are simulated and automatically arranged on the computer, so as to reduce the generation of waste as effectively as possible and reduce the production cost.

- Low processing cost. The production process is automated, which effectively reduces labor costs. Laser cutting itself has few consumables and high material utilization, further reducing the cost of the entire production line.

Technical features of the coil laser cutting production line:

- The CNC laser cutting machine adopts a professional system to control the motor synchronization. The cutting machine table is a crawler type cutting table, and the crawler type is equipped with a needle plate type cutting strip. During processing, the cutting table is synchronized with the unwinding servo feeding and runs at the same speed. Realize coil sheet cutting. It is suitable for the processing of metal coils within 3mm, the repeated positioning accuracy can reach ±0.03mm, and the positioning accuracy is within ±0.05mm/m.

- The body of the CNC laser cutting machine adopts a steel plate welding structure, and is tempered at high temperature to completely eliminate welding stress. During machining, CNC gantry milling machine is used to process the guide rails and rack mounting surfaces on both sides of the bed at one time, ensuring the consistency of the accuracy of the guide rails and rack mounting surfaces on both sides of the rack.

- The straightening wheel of the leveling machine is made of bearing steel, and the surface is thickened and electroplated, which is durable and wear-resistant. The operation is simple and convenient, all the straightening wheels are geared, and have their own backup pressure wheels, which can effectively enhance the rigidity of the straightening wheels and improve the quality of the straightening.

In summary, the coil laser cutting production line is an advanced manufacturing technology with CNC technology as the core and combined with computer technology, communication technology and database management technology, which is suitable for the production of large quantities of parts.

technical parameter of the Automatic Coil Fiber Laser Cutting Machine :

Running speed: 100m/min

Acceleration: 1.0G

X/Y is set as accuracy: 0.05mm/m

X/Y repeatability is set as accuracy: ±0.05mm

Working voltage: 380V/50Hz

Laser power: 700W

Machine power: 14KW

Machine tool operating temperature: 0℃-40℃

Operating humidity of machine tool: ﹤90%

Loading rack load: 8t

Open flatness: ±0.05mm

Openable plate thickness: ≤2mm

Kaiping width: ≤1300mm

Feeding system accuracy: ±0.2mm

coil

coil