Flexible bending center machine detailed explanation of machine performance characteristics and advantages

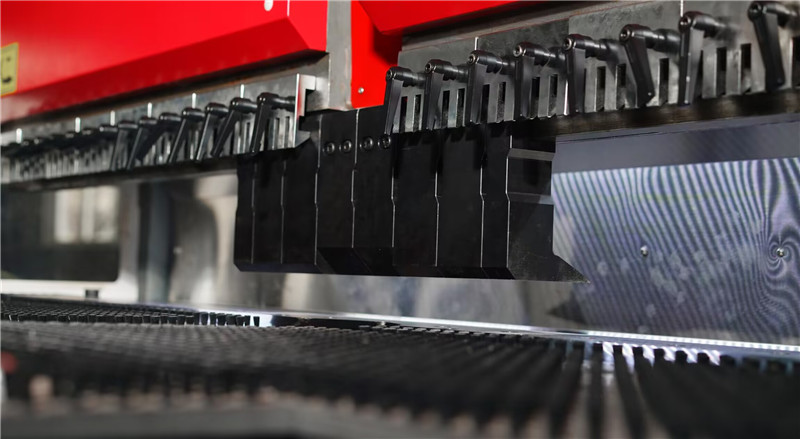

The advantage of the flexible bending machine is that it is not limited by the column spacing and throat depth of the C-type structure frame design, and can make full use of the bending machine for processing, which is more flexible and convenient. Moreover, its servo design allows rapid start and stop of the machine, and the processing speed is fast, which can shorten the processing time.

The advantage of the flexible bending machine is that it can automatically bend the four sides of the sheet in turn, realizing automation. The universal bending die can realize double side bending of plates. The CNC positioning device is used for automatic positioning, and the multilateral bending is completed at one time.

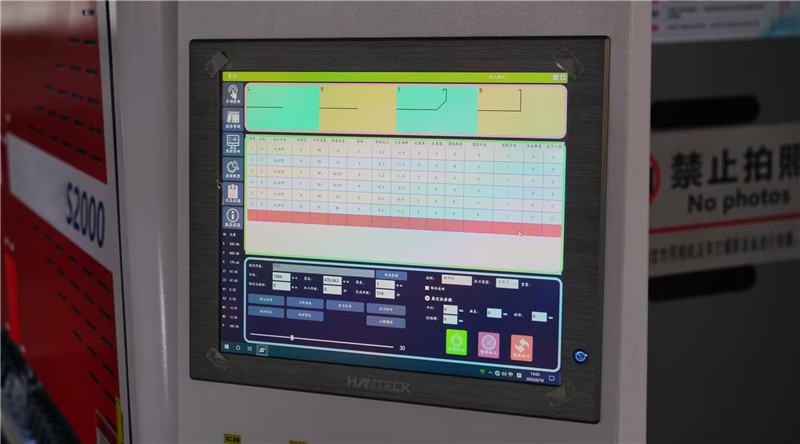

The flexible bending center adopts a new generation of CNC system, which is specialized in the development of CNC equipment system. Through the in-depth development of Zhihang CNC Company, it accurately realizes the perfect matching of all axes of the equipment for simultaneous linkage, and the program programming is faster and easier;

Flexible bending machine is suitable for new energy, home appliances, electric power, western kitchen, elevator, communication, network computer cabinet, medical machinery, fashion home, sheet metal processing, etc

Extended data:

Main performance characteristics of flexible bending machine:

High precision and efficiency

PM series is a new generation of fully automatic multilateral bending center, which is a benchmark product for the sheet metal manufacturing industry to enter into automatic production. It not only greatly saves manpower, but also the bending speed is 3 times of the CNC bending machine, reaching 0.5 s/time. Full servo control can control the product accuracy within 3S.

Product function

Zhihang flexible bending center, sheet metal bending without mold, can bend various complex shapes; The equipment is equipped with a pure electric servo system to replace the hydraulic drive, which has the advantages of environmental protection, fast speed, high accuracy, maintenance-free, etc; Zhihang Flexible Bending Center is a high-tech product developed and produced for the sheet metal industry to improve production efficiency, reduce labor intensity and enhance corporate image!

Its structure and characteristics:

Operating instructions and precautions: The power supply used by the equipment must be the same as the power supply type specified on the nameplate, and the grounding must be accurate and reliable;

Ø Before powering on, make sure that there is no foreign matter on the machine, and keep personnel away from the machine;

Ø The staff should not wear too loose clothes, and the cuffs and collar should be tightened to avoid winding, squeezing and other accidents;

Ø If the staff has long hair, they should tie it up to avoid winding and squeezing accidents;

Ø Press the emergency stop button immediately in case of any abnormality;

Ø When repairing the equipment, the power must be cut off first to prevent electric shock or mechanical injury;

Ø The power cord shall not be placed on the walkway or stacked on the power cord;

Ø When more than two people operate the machine, they should coordinate with each other. In case of emergency, the staff should press the emergency stop switch in time to stop the machine;

Ø At any time, the staff should not put their hands or other parts of the body close to the movement space of the internal parts of the machine to prevent winding or squeezing;

Ø Do not place tools and other sundries on the workbench and other surfaces of the equipment or inside the equipment to prevent damage to items or equipment;

Ø Regularly check whether the machine operates normally, and regularly fill or replace lubricating grease;

Ø Regularly or frequently check the power supply and switch wiring for damage to prevent leakage accidents.