sheet metal cnc V grooving Machine v groover machine operation processures

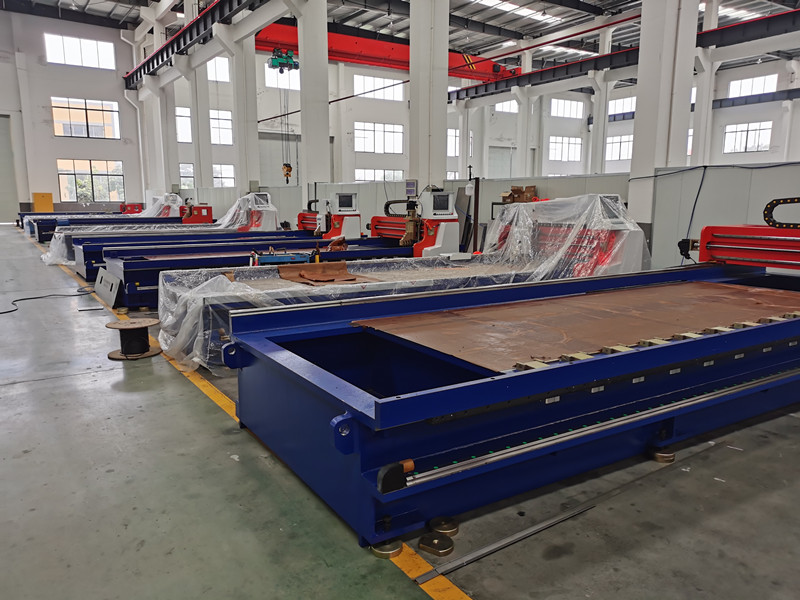

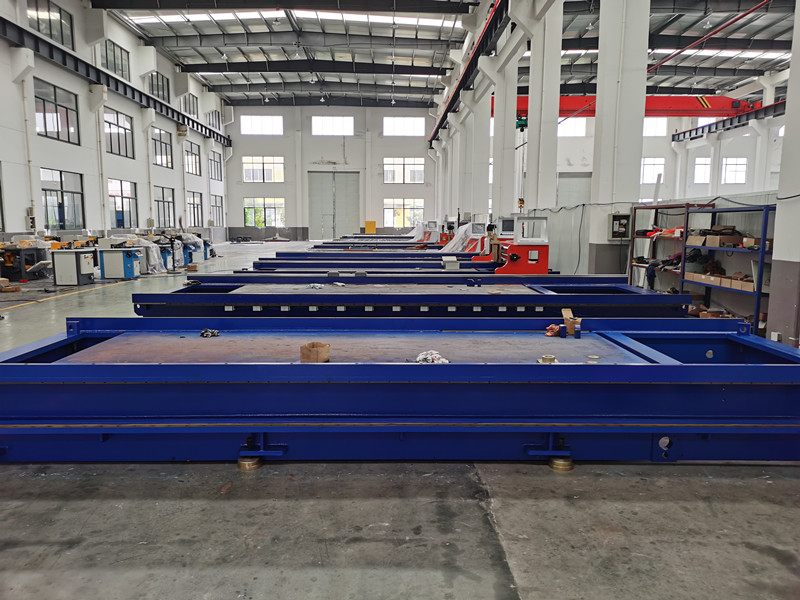

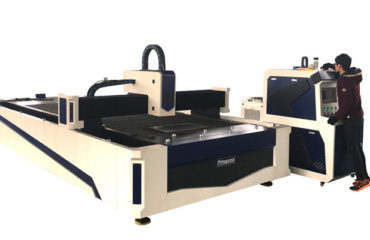

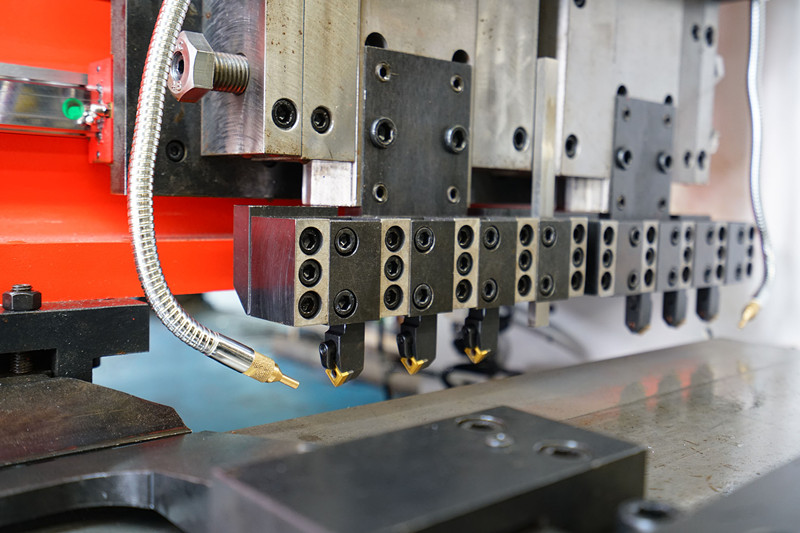

Primapress company produces the sheet metal v grooving machine clamping of workpieces using automatic hydraulic clamping device,

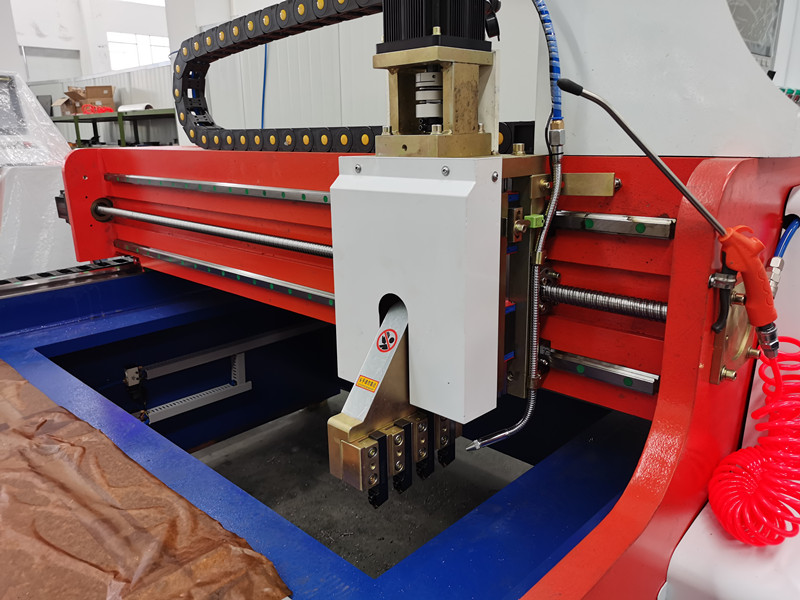

tool feed using the German BECKHOFF PLC control display, large-screen touch display, knife frame movement speed using servo motor

without extreme speed regulation, easy and reliable operation, good processing positioning accuracy, high production efficiency.

also ,Primapress brand v groover machines has following Product Features:

Advantages: conventional machine is clamps hold the sheet metal moving over the working table, so the sheet surface is

very easy to be scratched. Now this machine’s biggest advantage is sheet metal fixed, has no relative motion. the work piece is protected perfectly,

especially for use in mirror stainless steel plates on decoration, and so that the machine has a high processing speed.

We’ll introduce you to the V groove cutting machine:

Operational guidance for V grooving machine

- Before the operation of the machine tool, must carefully check the tool and nuts and screws are firm, if found loose phenomenon, must be tightened in time.

- Pay attention to the cutting direction when installing the cutting tool, do not reverse.

- The main knife is clockwise steering.

- Before feeding the groove, make sure that the pneumatic device is open and press the workpiece on the movable push table and on the tight positioning plate,

- and the hand is not allowed near the knife edge.

- When the machine tool failure should immediately cut off the power supply, and stop the operation, send special personnel to repair, do not run the machine tool fault.

- The material before processing should first check the tool whether there are nails, sand and stone joints, etc., to prevent damage to the knife tool flying injury.

- Cutting off the power supply of the machine tool before cleaning, lubricating oil, and removing the saw blade and cleaning debris.

- Machine tools must be operated, adjusted and maintained by special personnel, not familiar with the use of machine tools;

- Workers should wear earplugs, goggles, and other labor protection equipment to avoid damage to the body.

- The maintenance of the sheet metal grooving machine is carried out according to the system of operation, maintenance, and maintenance of equipment.

V grooving machine notes

In order to ensure the normal operation of the machine tool, reduce guide rail, ball screw, tool wear. All active parts

of the machine should be lubricated on time, so must pay attention to the following points:

- Before starting the machine, operate the hand-operated centralized oil injector, lubricate the moving part of the planer frame,

- twice a shift, and use a butter gun to lubricate the moving part of the back tube once a week.

- Groove ready” button for automatic V grooving machine before grooving ready button, do not press this button during grooving.

- Enter the new program, press the “emergency stop switch” to open, and then press the “tool forward” key to groove.

- No gloves should be worn during the operation of the V groover machine, and no “long hair” should be approved for operation.

- CNC V Grooving machine work must be strictly in accordance with the operation order.

- When grooving, programming feed must not be too large, so as not to damage the tool and press instability.

- During the operation of each processing 15-20 times, check whether the positioning sleeve loose.

- The injected pressure oil must be filtered to ensure that the oil is clean (regular inspection, pressure oil deterioration needs to be replaced).

- Under normal working conditions, the oil plane should be kept at 2/3 of the oil ruler and must not be lower than the red line.

- Equipment failure, please immediately press the stop button and feedback to the relevant responsible person.

- After the operation, the iron debris and other sundries on the guide slot of the hydraulic clamp of the worktable must

- be cleaned and the machine tool should be kept clean and tidy.

The above is about the operation of the V grooving machine and its matters needing attention. After reading this article,

I believe you have a further understanding of the V grooving machine. Primapress is a professional V grooving machine manufacturers.

If you have any needs, please contact us as soon as possible. We will serve you all the time!