The development process and production process of metal plate CNC bending machine molds

The development process of metal plate CNC bending machine mold

The development history of metal sheet CNC bending machine molds is as follows:

From the perspective of the development process, high-speed steel is the main representative of traditional mold materials, but Germany first developed and widely used mold materials for cemented carbide sheet metal CNC bending machines. Later, Sweden and the United States separately synthesized synthetic diamonds, and the metal plate CNC bending machine molds

mainly cutting into a period represented by cemented carbide materials.

Later, people synthesized polycrystalline diamond, which solved the problem of low quantity and expensive natural diamond, and expanded the application scope of diamond sheet metal CNC bending machine molds to aviation, automobiles, electronics, stone and other fields. The selection of die materials for sheet metal CNC bending machines is the basis for successful cutting.

Compared with cemented carbide, the speed of polycrystalline diamond sheet metal CNC bending machine molds reaches 4,000 meters per minute, while cemented carbide is only a quarter of that. From the point of view of life, the life of polycrystalline diamond sheet metal CNC bending machine molds is generally twenty times that of traditional products. From the point of view of the processed surface quality, the effect of polycrystalline diamond is 30% to 40% higher than that of cemented carbide. In addition, the development of CBN (three-dimensional boron nitride)

hard material sheet metal CNC bending machine molds and surface-coated sheet metal CNC bending machine molds are also indispensable for the advancement of cutting processing technology.

Now people gradually abandon the method of using aluminum alloy to cover directly, instead of directly bending and winding composite materials. In addition, the use of titanium alloys is also increasing. Compared with the past, the new method can greatly reduce the weight of products, save fuel and energy consumption, which is particularly important for products such as large passenger aircraft.

The above is an introduction to the development history of metal sheet CNC bending machine molds, thank you for reading.

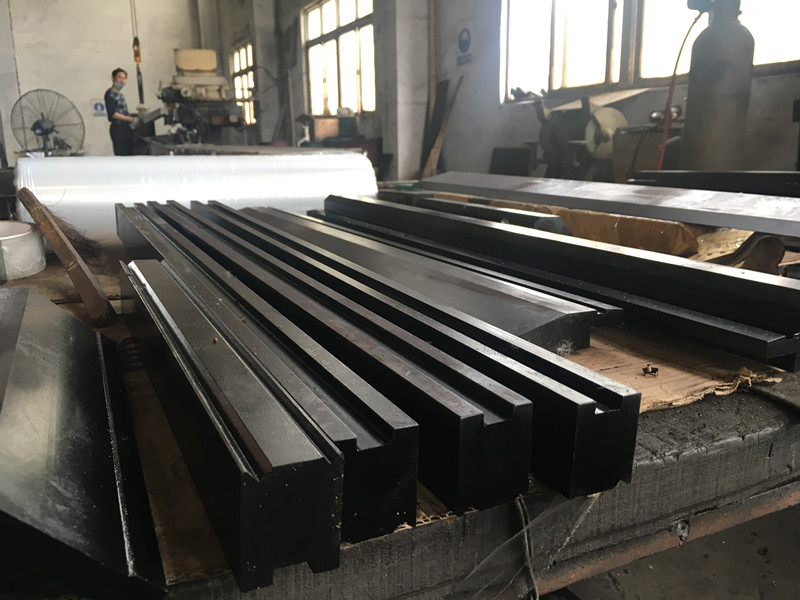

The production process of the bending machine mold

The production process of the bending machine mold is as follows:

- Product drawing order (analyze and confirm production plan). The early participation of suppliers in this stage is mainly about technical discussions between customers and suppliers on product design and mold development. The main purpose is to allow suppliers to clearly understand the intent and accuracy requirements of the product designer’s design.

- Place an order for mold materials. 3. Carry out material quality inspection (size, material, performance). 4. Manufacturing (including turning, grinding, cutting, grinding, drilling, heat treatment, wire cutting processing). 5. Trial production type: (1) Initial trial production type: mold performance analysis, record the size of the first test flower sample, and conduct appearance quality inspection. (2) Next test type: a. Repair type record. b. Sample quality inspection records. 6. Submit samples to customers for confirmation, and ask customers to

- provide valuable feedback. 7. Mold production: (1) Record the quantity of precision blanking products. (2) The mold records spare parts. (3) Carry out product quality inspection and packaging warehousing. 8. After the die blanking is completed, the tip of the knife is finely ground, the oil is discharged, and it is easy to store, and the next blanking is performed.

The mold is a model. Products are made according to this model. But how the mold is produced may not be answered by most people except mold experts, but the mold has played an

irreplaceable role in our lives. Most of our daily necessities Molds are indispensable, such as computers, telephones, fax machines, keyboards, cups, etc. And bending machine molds are widely used in industrial production. For example, the covers of automobiles and motorcycle engines are also made with molds. More than 20,000 molds are used for various automobiles.

Therefore, the role of mold in modern life is irreplaceable.

The above is the production process of the bending machine mold, thank you for reading.